Description

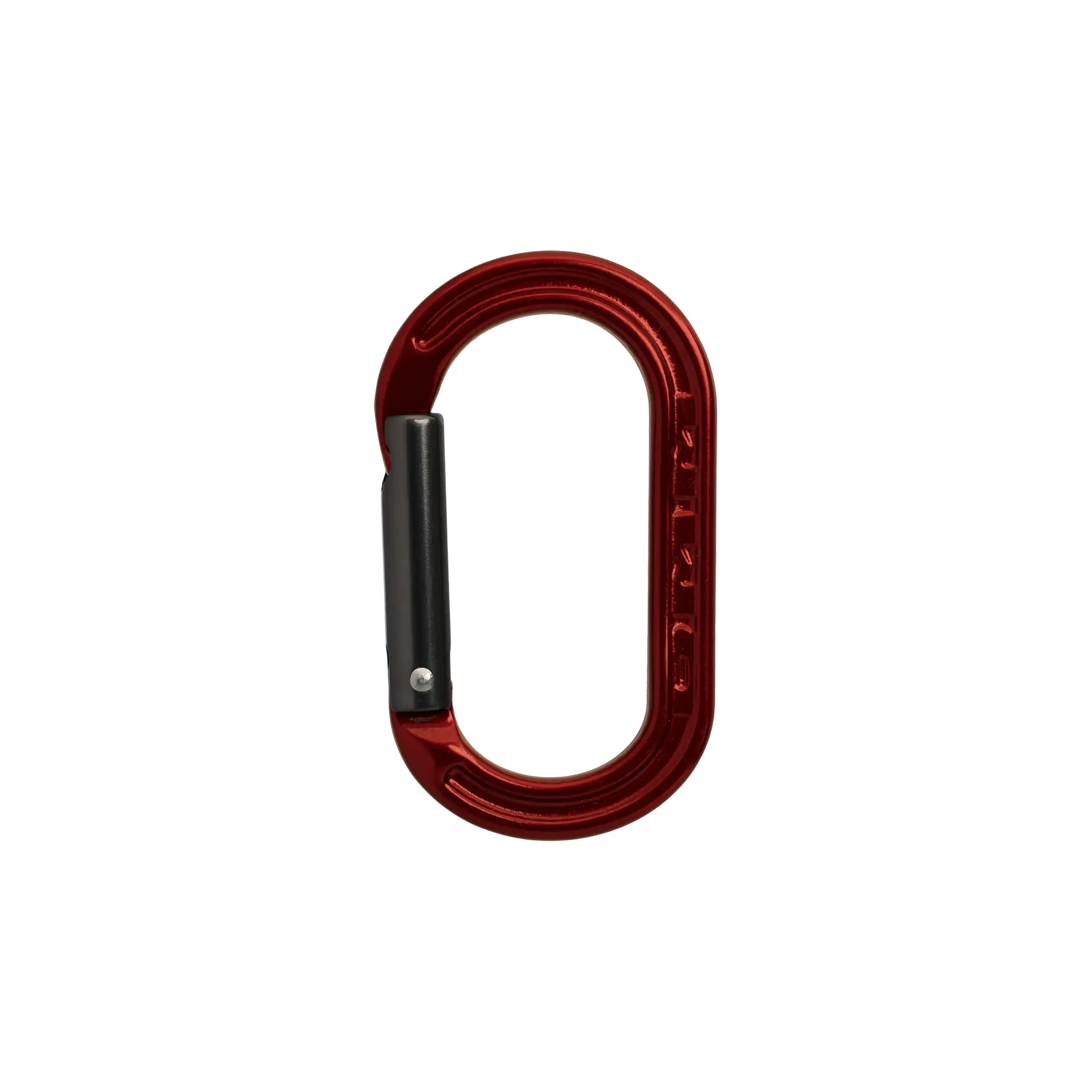

Despite its miniature size, the XSRE has all the features of it’s fully grown family. A clean nose stops your keys catching, I-Beam construction brings weight down to a minuscule 8 grams, and colour anodising means the XSRE stands out from the crowd.

Despite its miniature size, the XSRE has all the features of it’s fully grown family. A clean nose stops your keys catching, I-Beam construction brings weight down to a minuscule 8 grams, and colour anodising means the XSRE stands out from the crowd. It even rates to 4kN, more than strong enough for any non-PPE function you can think of.

| Product Name | Product Code | Colour | MBS (Major Axis) | MBS (Minor Axis) | MBS (Gate Open | Dimensions | Weight | Gate Opening (X) | Conformance |

|

XSRE Mini Carabiner

|

A531

|

Various

|

4kN

|

32 x 57mm

|

8g

|

31mm

|

Not PPE

|