Description

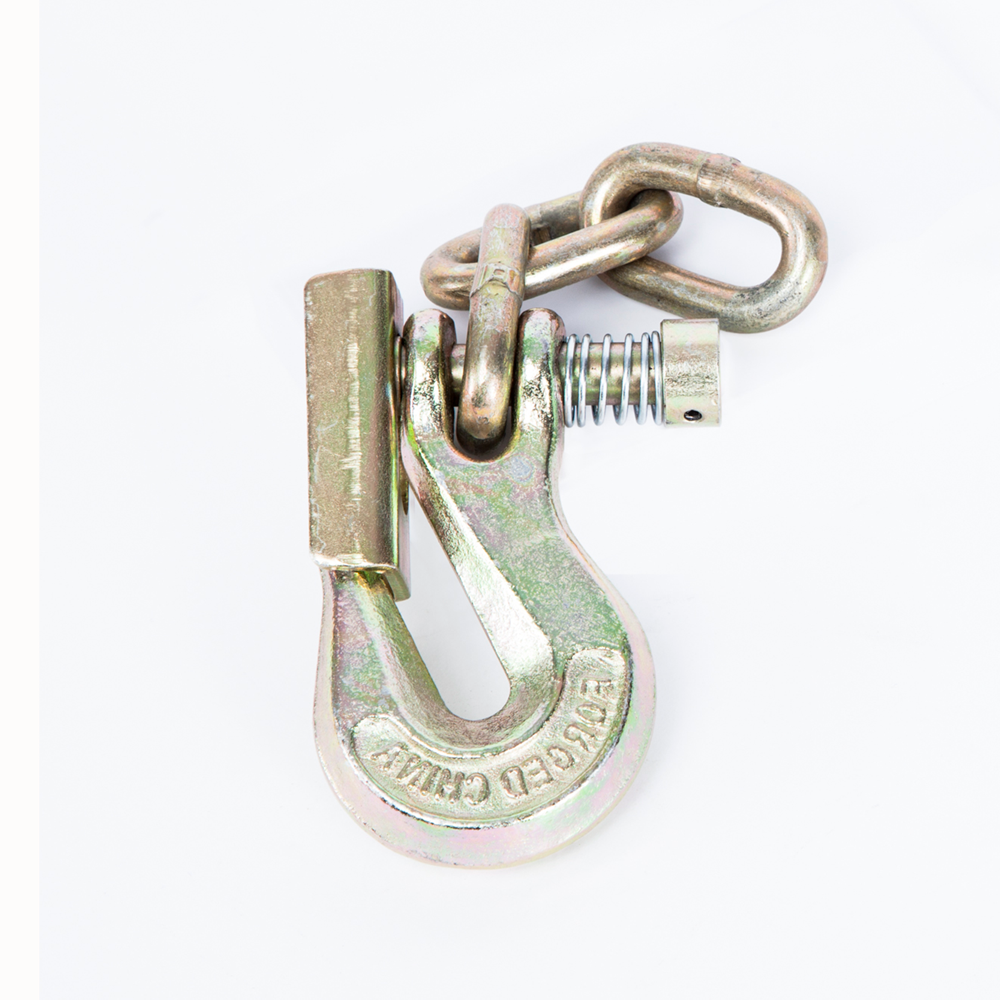

The Portable Winch Grab Hook – 7mm (5/16″) is a durable and versatile tool designed for heavy-duty lifting and pulling tasks. Made of stainless steel, this grab hook features a lightweight 76 mm diameter deep groove aluminum sheave, with stainless steel plates that swing open to easily install rope. The sintered bronze bushing on the stainless steel shaft provides 98% efficiency, ensuring smooth and reliable operation.

This grab hook is particularly useful for doubling the line, as the rope cannot accidentally come out of the block, providing added safety and security during use. It is also highly effective for redirecting a load or pulling upward on a hill, making it a valuable tool for a wide range of applications. The steel locking carabiners can be used to anchor the grab hook to a polyester sling, further enhancing its versatility and functionality.

With a smaller and lighter design than the PCA-1274 pulley, the Portable Winch Grab Hook – 7mm (5/16″) is easy to transport and maneuver, making it an ideal choice for on-the-go lifting and pulling tasks. The recommended rope diameter of 10 mm ensures optimal performance and compatibility with the grab hook, making it a reliable and efficient tool for various lifting and pulling applications.

SPECIFICATIONS

Minimum Breaking Load (metric) : 60 kN (6125 kg)

Working Load Limit (metric) : N/A

Material : Sides: Stainless steel. Sheave: Aluminum

WEIGHT & DIMENSIONS

Weight (metric) : 0,69 kg

Diameter (metric) : 76 mm

Length (metric) : 17 cm

Width (metric) : 11 cm

Height (metric) : 11 cm

ROPE

Minimum diameter (metric) : 6 mm

Maximum diameter (metric) : 10 mm

ADDITIONAL INFORMATION

Additional Information : Not designed for steel cable.

Additional information : The NEWTON is the International System unit for force; it is equal to the amount of net force required to accelerate a mass of one kilogram at a rate of one meter per second squared. — The WORKING LOAD LIMIT (WLL) is the maximum load which should not be exceeded under any condition. — The MINIMUM BREAKING STRENGTH (MBS) is observed during a destructive test. You should divide it by an appropriate safety factor.