Description

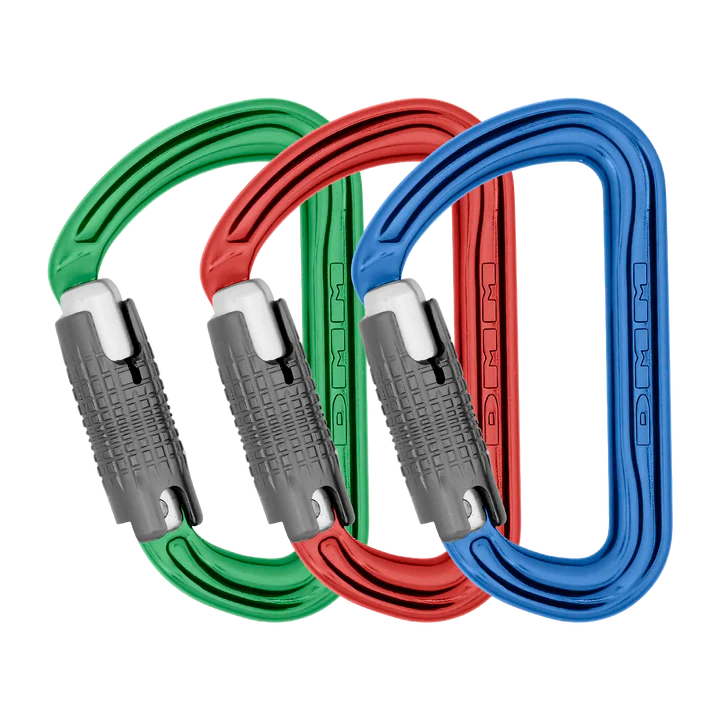

The DMM Shadow offset D is the most compact locking connector in the DMM Professional range and it is impressively strong for its size and weight. Perfect in any confined space or tower climbing situation where the overall weight and size of a system are crucial, the Shadow gives plenty of security reserves whilst feeling featherweight on a harness or in a bag. Hot forged I-beam back for increased strength to weight ratios.

Features

- Conforms to EN362:2004/B

- Small Offset D shape provides a very lightweight but strong connector

- I-Beam section for increased strength to weight ratio

- Keylock clean nose for snag free connection

- Hot forged and fully heat treated aluminium for lightness and maximum strength

- Anodised to BS EN ISO 7599:2010 class 10 E1 sealed for corrosion protection

- Ideal for general use when weight saving is important

- Individually marked for traceability

The DMM Multipacks are a simple and convenient way of identifying components within any system.

They are ideal for the training market to aid component identification from a distance, as well as being convenient for work teams and individuals in the safe organisation and operation of fall protection systems.

Locking Connector User Instructions

| Variant |

Strength

(Gate Closed) |

Gate Opening |

Weight |

Colour |

DMM Cat No |

|

Shadow LS

|

24kN

|

17mm

|

58g

|

Green/Red/Blue

|

A307-P3

|