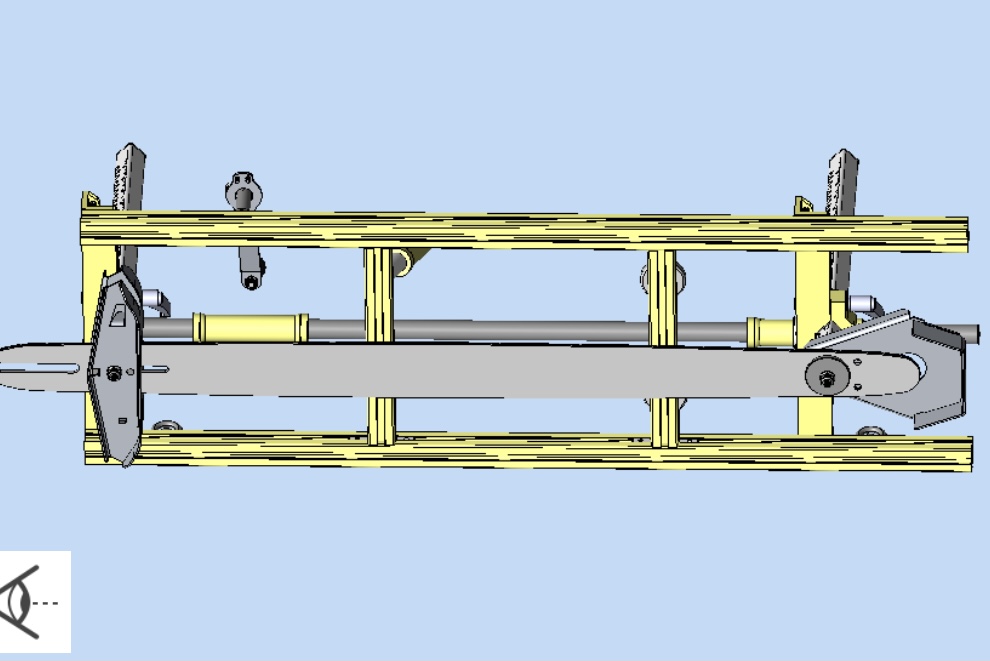

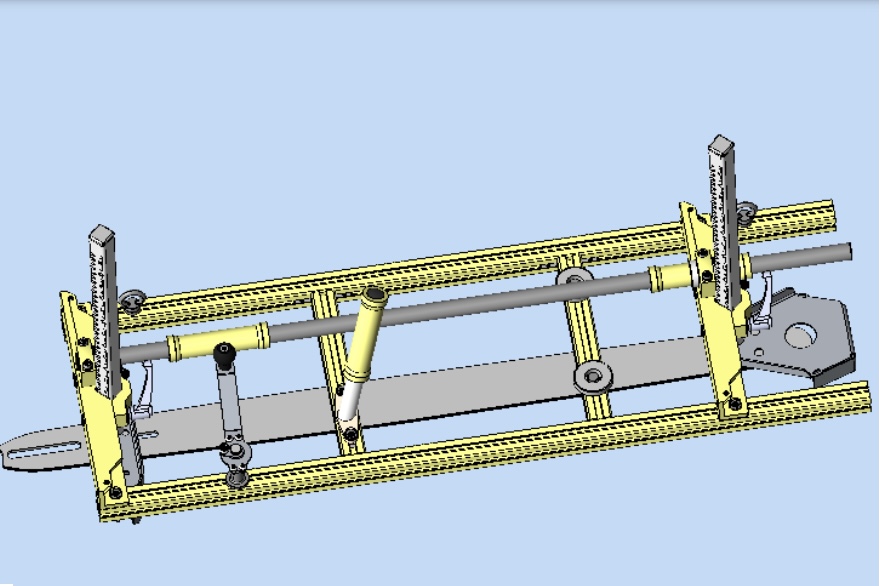

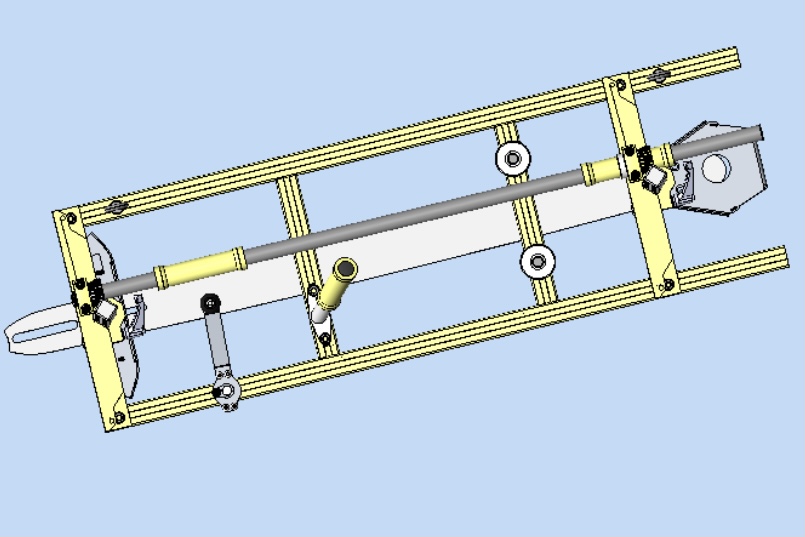

Panther Horizon Chainsaw Mill 4ft – 1.2m with GB 3.5ft – 1.07m Lo Pro Milling Bar

Designed by chainsaw millers for chainsaw millers.

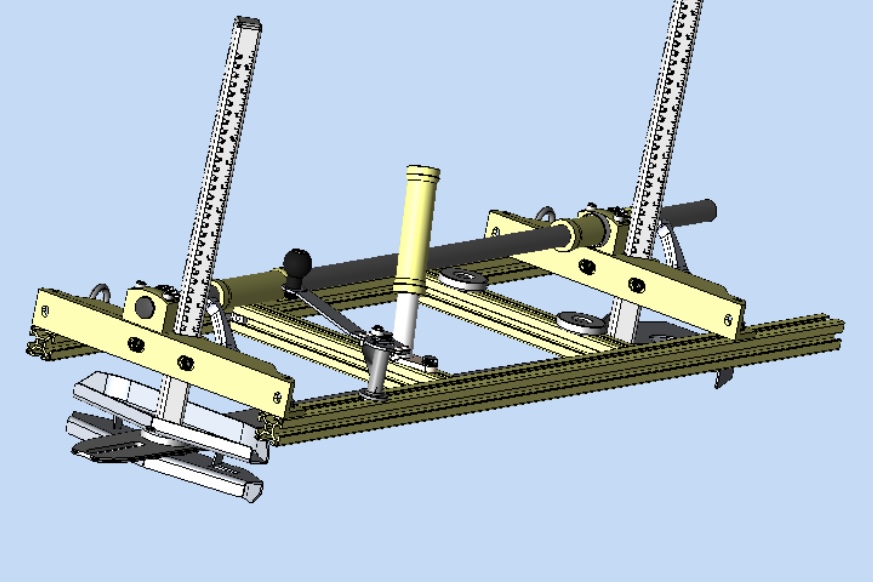

Re-designed from the ground up – most other chainsaw mills are copied from existing designs – the Panther Mill has been re-designed from scratch.

£698.12 Ex VAT

£837.74 Inc VAT

Description

Designed by chainsaw millers for chainsaw millers.

Re-designed from the ground up – most other chainsaw mills are copied from existing designs – the Panther Mill has been re-designed from scratch.

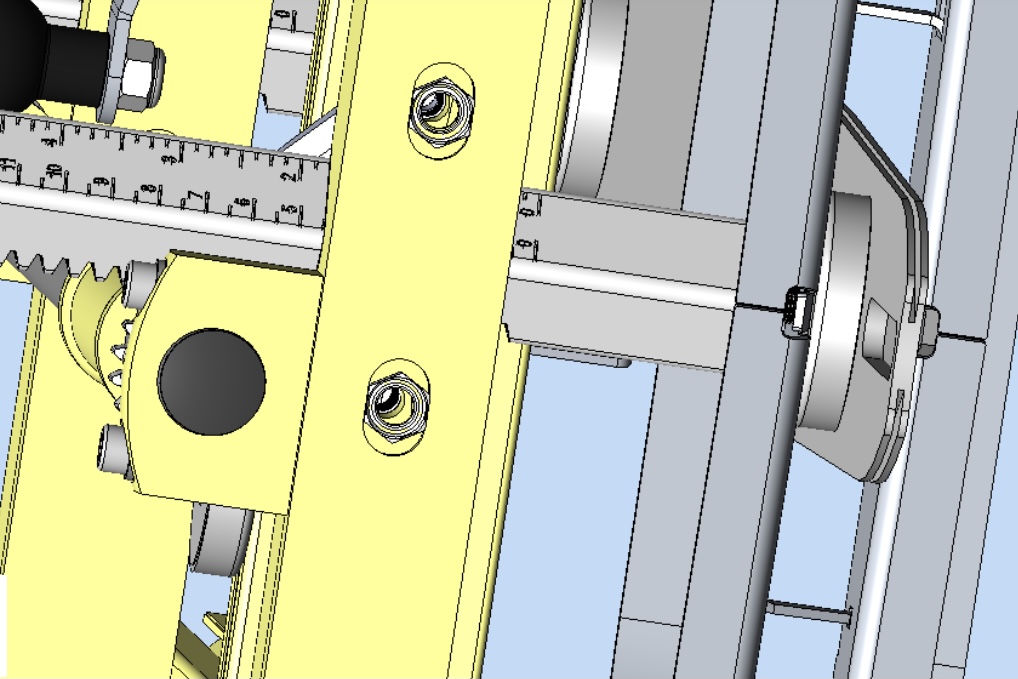

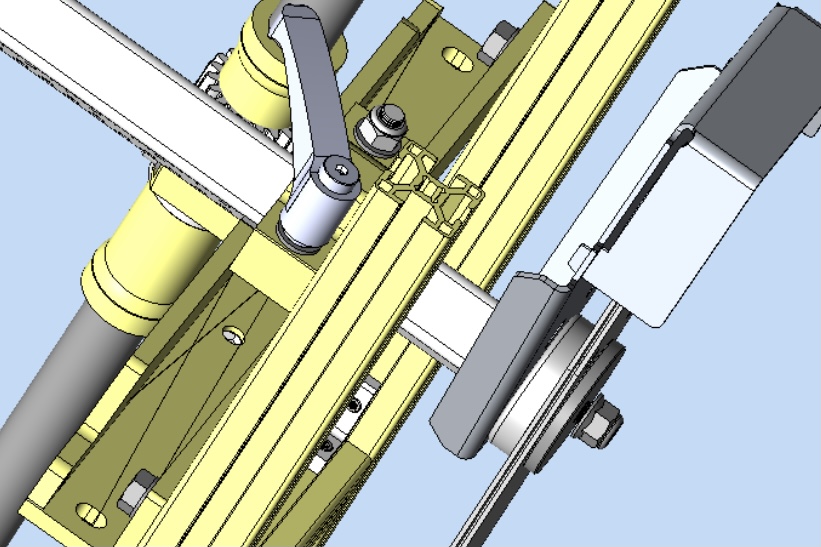

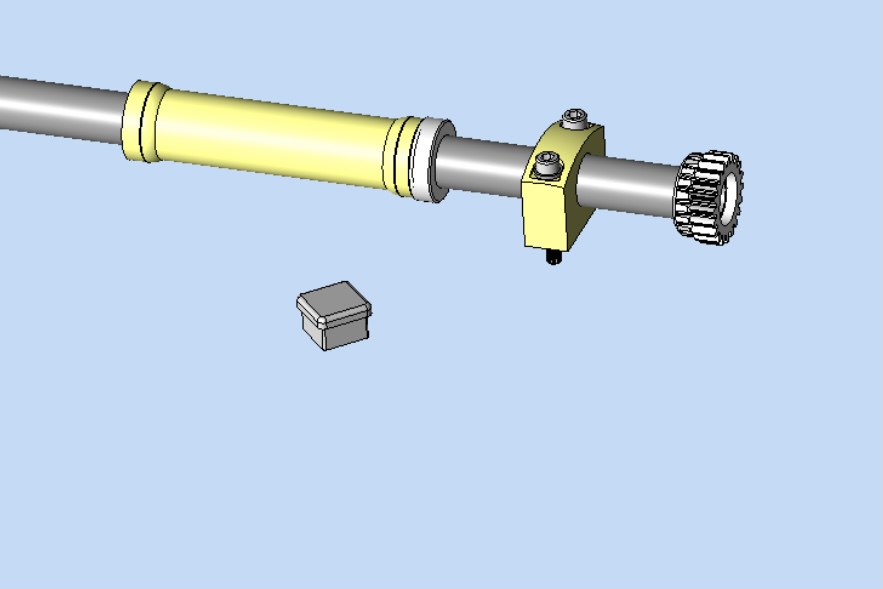

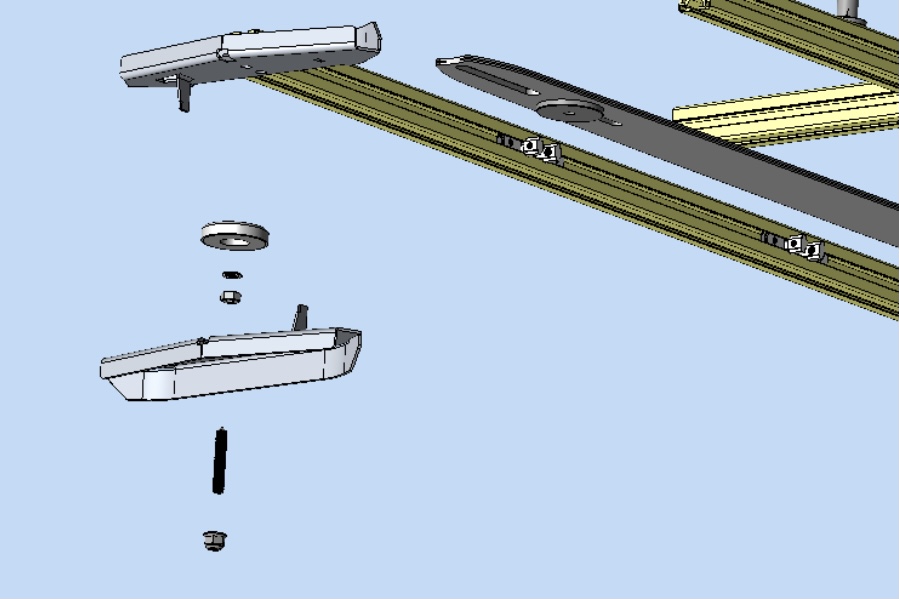

Height adjustment is tool-less and fast – in fact it is the fastest compared with any other mill on the market. Simply rotate the round handle to adjust how deep the mill will cut. No need to hold a spanner in one hand while trying to adjust the mill with the other.

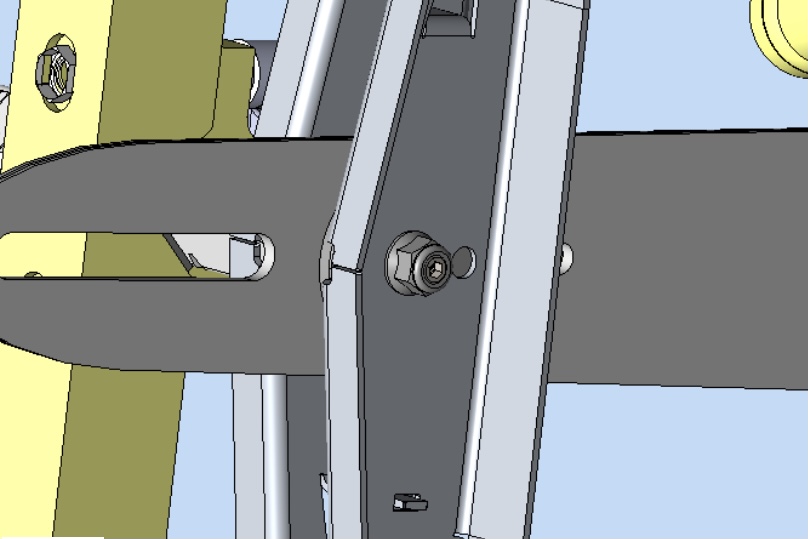

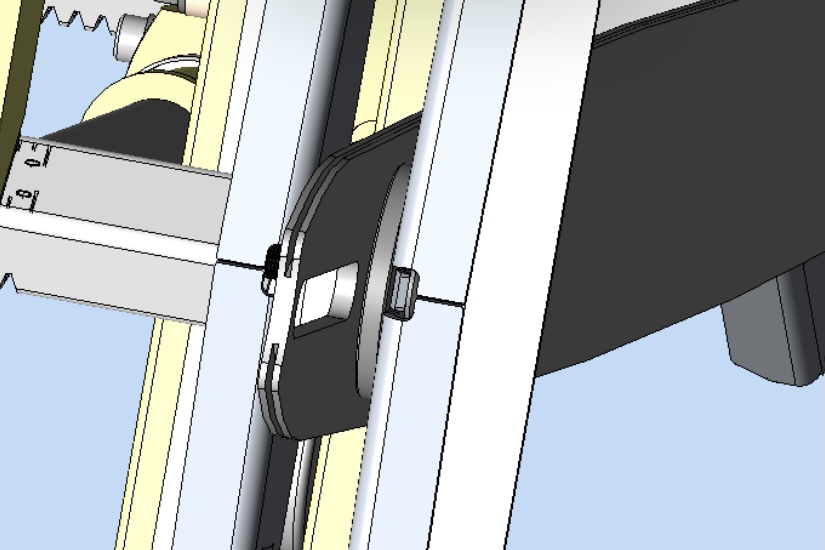

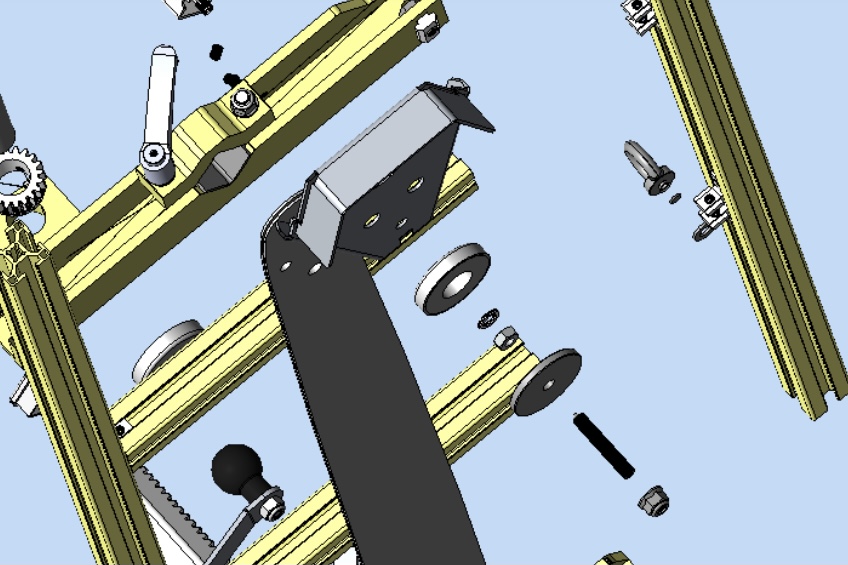

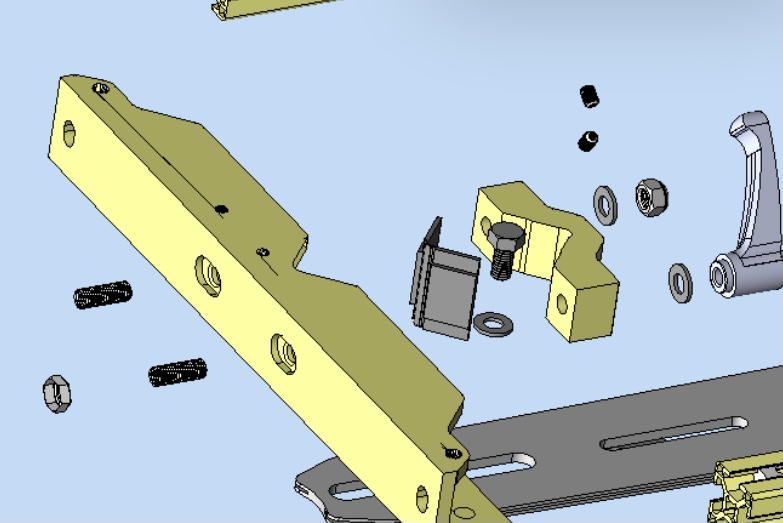

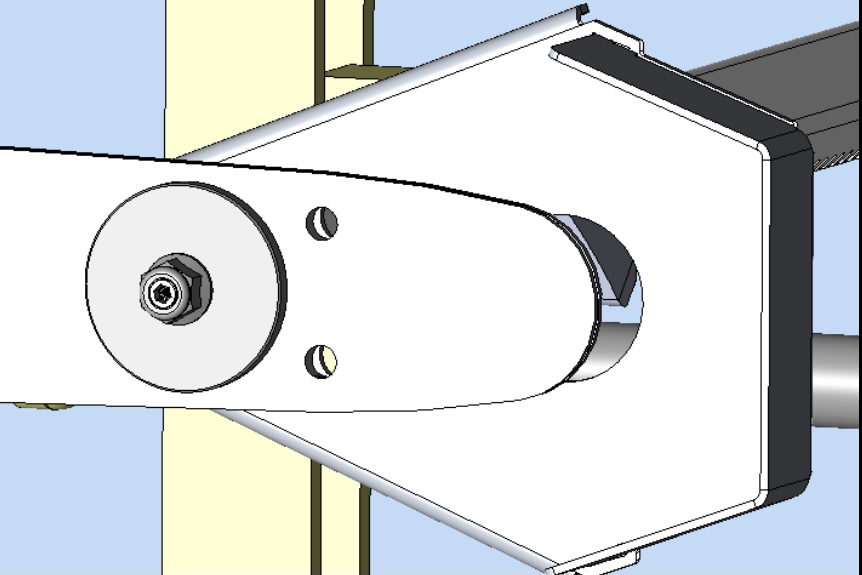

Attachment is the quickest of any chainsaw mill – easily bolt and unbolt your mill to your chainsaw.

The attachment to the saw is bolted not clamped – the saw can never slip in the mill.

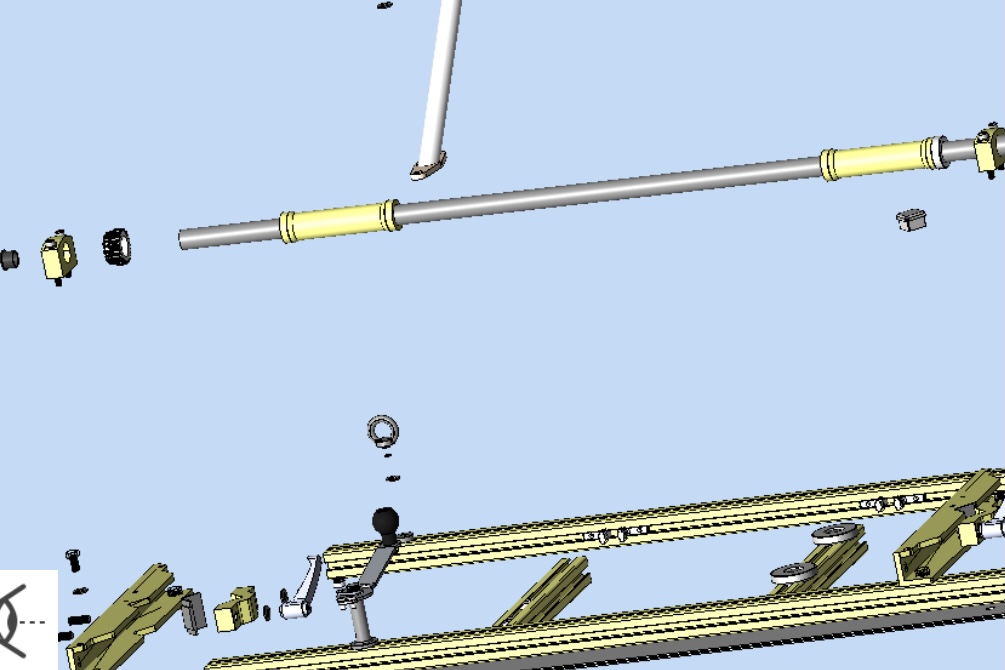

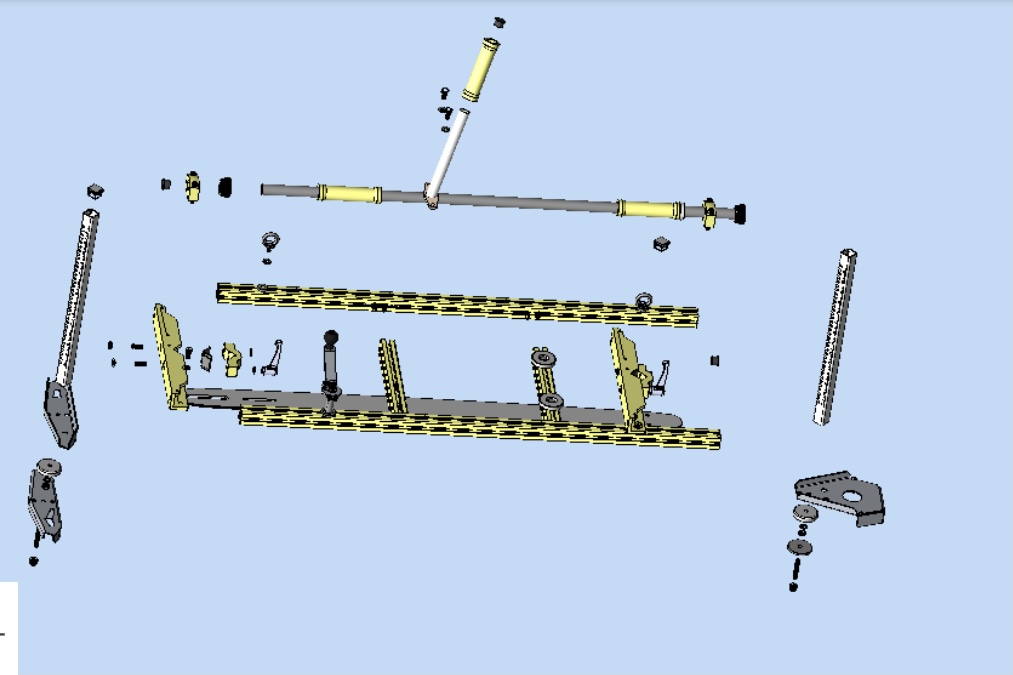

- 2x P-3/8LP-050-137 Lo Pro Ripping Chain 3/8 Lo Pro .050 137 drive links

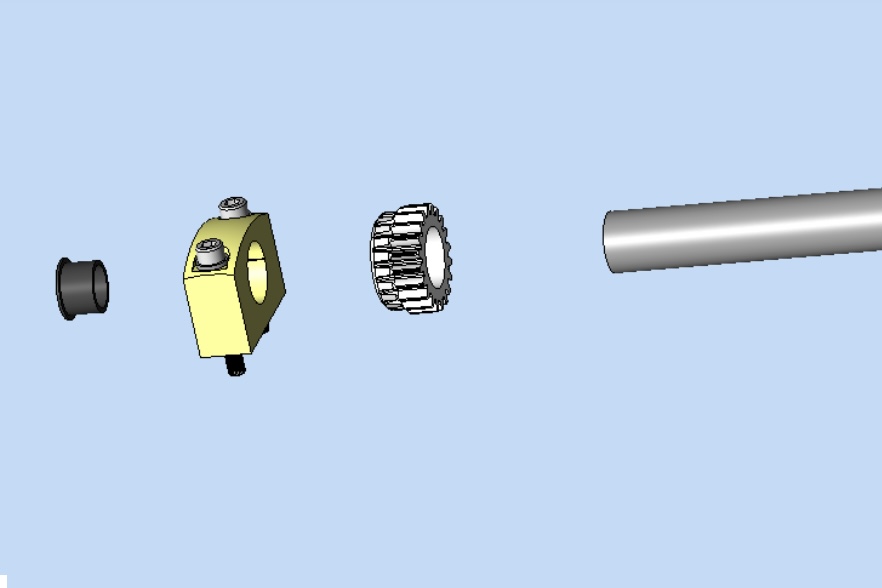

- GBR7L7 GB Lo Pro Drive Rim

- PW-MkIII-FK Panther Mk III Winch [FULL KIT]

- CS-PN Complete Panther Upright Nose End [Small 30mm Profile Mills]

- CS-PT Complete Panther Upright Thrust/Skid End [Small 30mm Profile Mills]

- P-SBBA Panther Black Bracket Assembly [Small 30mm Profile]

- P-CBHS Panther Cross Brace With Handle [Small 30mm Profile]

- P-CBMT Panther Cross Brace With Tools and Magnets [Small 30mm Profile]

- PM-SAK Panther Mill SMALL Accessories Kit

- P-48 Panther 48″[120cm] Profiles and Control Tube

- SNHS42-50WR 42″[107cm] GB Lo Pro Milling Bar[Single Slot] 3/8 Lo Pro .050 137 drive links

The mill is designed to be used with special GB Lo Pro milling bars which are thinner and narrower than existing chainsaw bars for a faster, cleaner cut.

Panther Mills automatically come with a full winch set up to make milling 80% easier than pushing by hand [this is now the new lighter custom Panther winch].

There is a dedicated Panther First Cut System to ensure your first cut is table top flat. This first cut system can be extended and widened indefinitely. It is the best on the market today.

In the long term additional functionality will be built into the Panther Mill that currently does not exist anywhere else – but you’ll have to watch this space to see!

Additional information

| Weight | 2 kg |

|---|---|

| Dimensions | 1 × 1 × 1 cm |

| Brand | Panther Mills |